Using petroleum coke as the basic raw material, the smelting process has high temperature, low impurities, and fast decomposition rate in molten iron, which can continuously add graphite cores to the molten iron.

Product Information:

Silicon Carbide: Model JDX-90-03

Size range: 40-90mm

Product Specifications:

SIC | 90-92% |

Fe2O3 | ≤2% |

F.C | ≤2% |

S | ≤0.03% |

AL | ≤0.1% |

Product Overview:

1.Jiuding SiC is a strong deoxidizer to purify the liquid iron, improve the casting quality and reduce the cost.

2.Jiuding SiC has stable carbon-silicon ratio,with low content of Al,P,and inert gas.

3.Effectively control the corrosion of iron oxide(FeO to the furnace lining,and avoid producing fayalite FeO-SiO2)to extend the life of furnace lining.

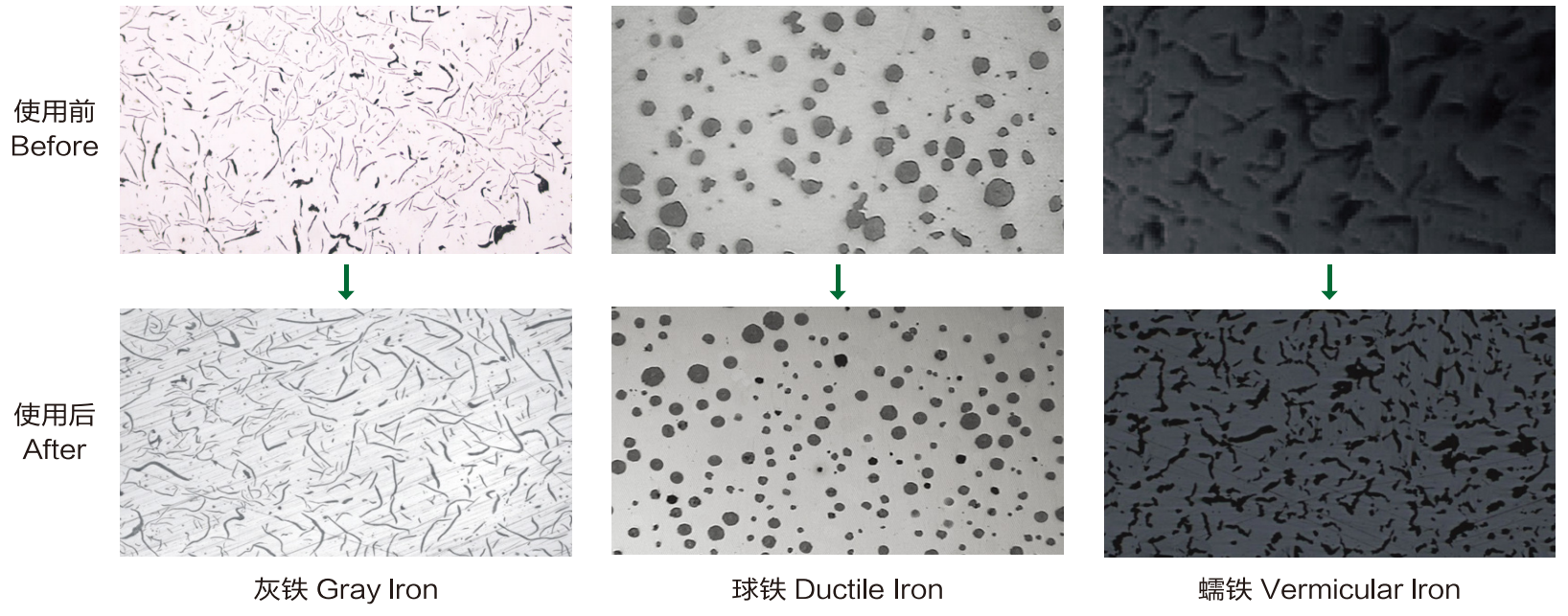

4.Long-acting inoculation effect:there is a SiO2 cover on the surface of SiC crystal which could slow down the nucleaus releasing speed,and result in reducing tendency of cementite and chill,optimizing graphite morphology and stabilizing machinability of the casting.

5.In ductile iron casting,the deoxidation pre-treatment by Jiuding SiC could reduce the ablation and oxidation of Mg, which could save the nodulizer by 10%and prevent chill.

6.In gray iron casting,SiC in charge could prevent the precipitation of carbide,delay the inoculation fading,and prevent chill.

7.Jiuding SiC is made of petroleum coke with centralized and controllable particle size distribution,and easy to use.

Case Analysis:

Application field:

Qingdao Jiuding Casting and Metallurgy Materials Co., Ltd. is a specialized company engaged in the production, operation, and service of casting auxiliary materials.

Copyright © 2023-2024 Jiuding Casting and Metallurgy Materials Record Number:鲁ICP备15042007号

Technical Support: WDL